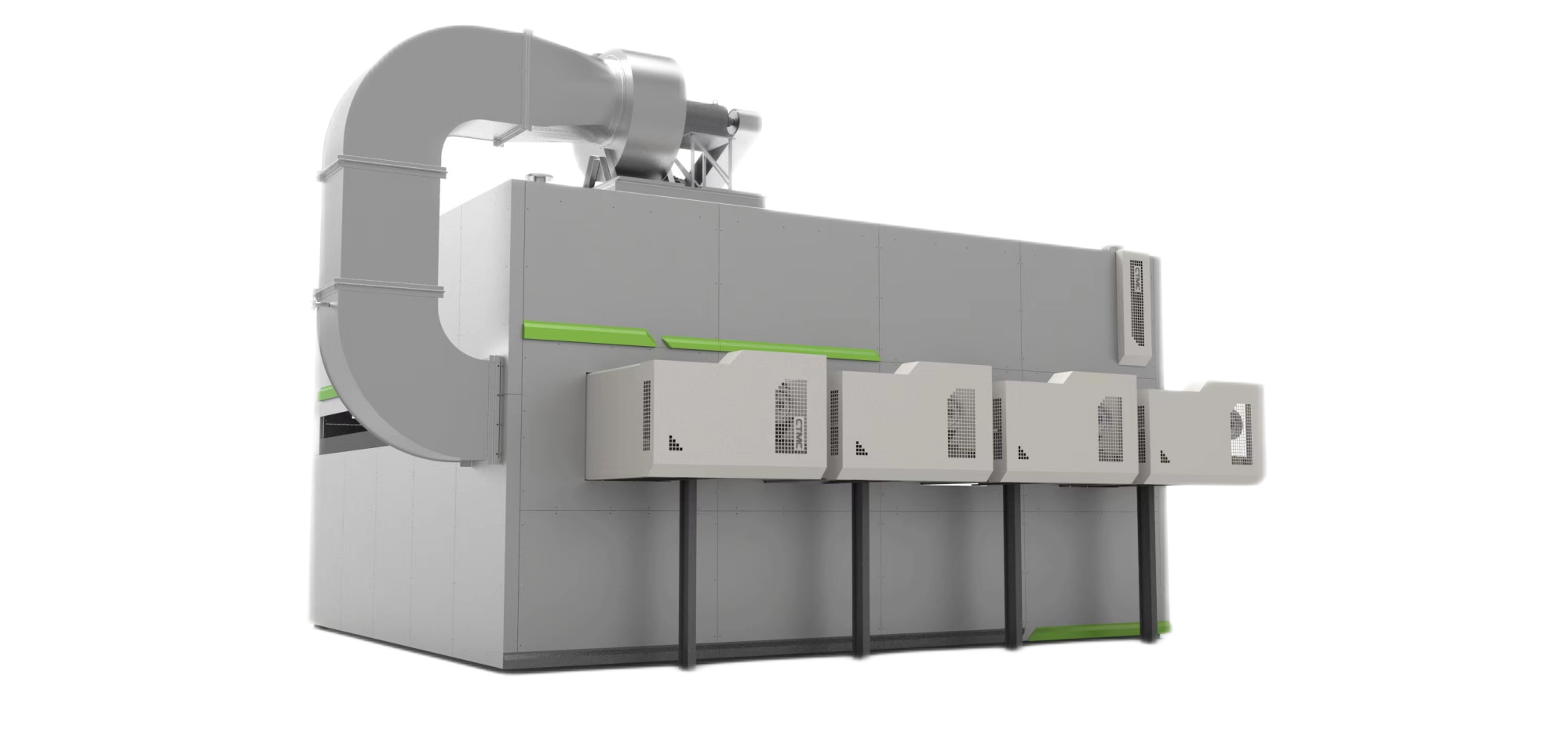

A hydroentangling production line is a manufacturing equipment used for producing nonwoven fabrics, and the drying machine plays a crucial role in this production line.

Here is an introduction to the drying machine:

Purpose and Function: The drying machine, in the context of a hydroentangling production line, primarily serves the purpose of drying the wet fiber materials, typically polyester, nylon, polypropylene, etc., after the hydroentanglement process. Its objective is to achieve the desired moisture content and quality standards, which is a critical step in producing high-quality nonwoven fabrics.

Working Principle: Drying machines in this context usually employ a hot air circulation system. They heat the air and direct it into a drying chamber. Wet fiber materials are placed on a conveyor belt, and as the hot air circulates while the belt moves, moisture gradually evaporates, ensuring the gradual drying of the materials.

Drying Methods: Drying machines can utilize various drying methods, including hot air drying, infrared drying, microwave drying, etc. The choice of drying method depends on production line requirements and material characteristics.

Temperature and Speed Control: Drying machines typically feature temperature and speed control systems to ensure the stability and consistency of the drying process. These control systems can be adjusted according to different production needs.

Energy Efficiency: Considering energy consumption and environmental concerns, modern drying machines are designed to efficiently utilize energy, reducing production costs and environmental impact.

Safety: Safety is also a critical consideration for drying machines, including fire prevention and ensuring the safety of workers. Therefore, drying machines are usually equipped with various safety devices and monitoring systems.

Customization: Drying machines can be customized to accommodate different types of nonwoven fabric materials and production scales, depending on specific production requirements.

Advantages of Rotary Drum Hot Air Drying:

Rotary drum hot air drying is a commonly used drying method in hydroentangling production lines. Here are its advantages:

Uniform Drying: Rotary drum hot air drying ensures even heating and drying of fiber materials within the drum, minimizing moisture variations.

High Efficiency: This drying method typically offers high drying efficiency, quickly reducing moisture levels to meet production demands, thereby enhancing production efficiency.

Energy Savings: Rotary drum hot air drying systems are often designed for excellent energy efficiency. Through precise control of hot air circulation and temperature, they can reduce energy consumption, lowering production costs.

Versatility: This drying method is suitable for various types of nonwoven fabric materials, including different fiber types and thicknesses.

Ease of Control: Rotary drum hot air drying systems come equipped with advanced temperature and humidity control systems, allowing precise control of the drying process to meet different product specifications.

In conclusion, rotary drum hot air drying is a commonly used and efficient drying method in hydroentangling production lines. It ensures the production of high-quality nonwoven fabrics while offering advantages such as energy efficiency and ease of control. It finds widespread applications in the textile and nonwoven fabric manufacturing industries.

Post time: Sep-25-2023