- Raw Material Preparation: Initially, the raw materials are prepared. Raw cotton is typically supplied in bales or large bags and needs to be loosened and unpacked. This stage usually involves the use of equipment for loosening and conveying the raw cotton to the next processing stage.

- Cleaning and Impurity Removal: At this stage, the raw cotton undergoes cleaning and impurity removal processes. Equipment such as openers, dust collectors, and magnets is used to remove impurities, dust, cotton seeds, and other unwanted substances. This step is crucial to ensure the quality of the final product.

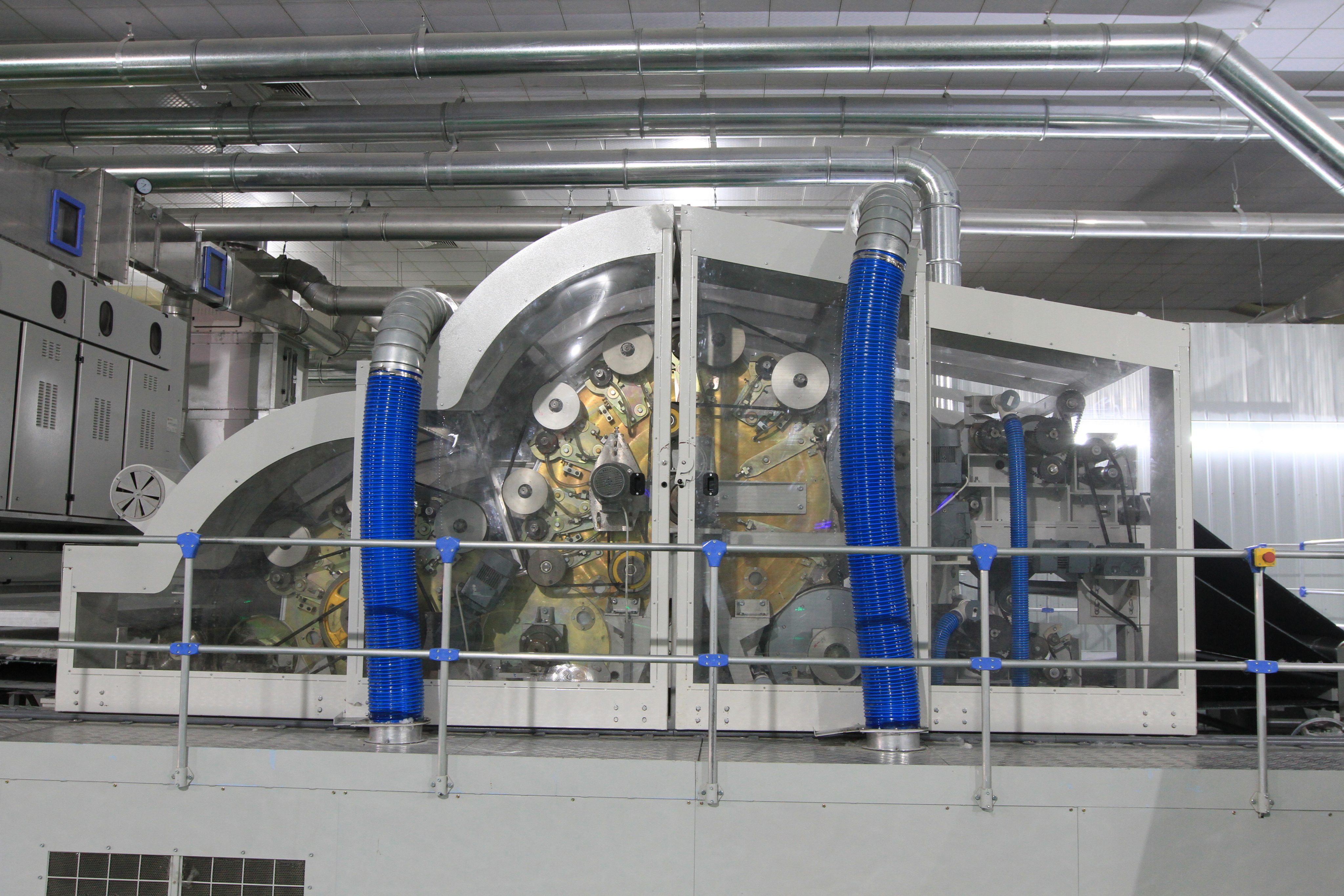

- Carding or Combing (as needed): If the end product requires longer and more uniform cotton fibers, carding or combing may be performed. This step typically involves the use of carding machines or combing machines to separate and align the cotton fibers.

- Opening: In some cases, raw cotton may become tightly compressed due to transportation or storage. The opening process involves using opening machines to loosen the cotton fibers, preparing them for further processing.

- Fiber Blending (if necessary): In certain situations, different types of fibers (such as cotton fibers, synthetic fibers, or wood pulp fibers) may be blended to achieve the desired fiber blend ratio. This stage often involves the use of blending machines or mixing equipment.

- Conveying and Preparation: The processed raw cotton fibers need to be conveyed to the feeding area of the hydroentangling machine and prepared to ensure an even feed into the hydroentangling process.

These stages may vary somewhat depending on the configuration of the production line, product requirements, and the type of raw materials used. However, these stages are typically the fundamental steps in the pre-processing of raw cotton fibers for the hydroentangling process, ultimately leading to the production of nonwoven fabrics or related products.

Post time: Sep-11-2023