CTMTC has superior performance in chemical fiber equipment and is a trusted supplier of textile machinery equipment. CTMTC‘s chemical fiber equipment is mainly divided into PET Filament Line and PET Staple Fiber Line. Among them, the PET Filament Line includes FDY production line and POY Production Line. FDY machines can produce knitted fabrics, woven fabrics, and sewing threads for making clothes, home textiles such as towels, carpets, tapestries, as well as industrial silk, ropes, etc.

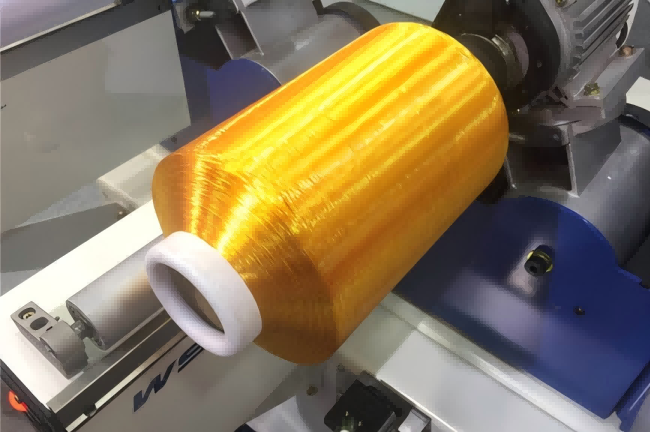

As your trusted supplier, CTMTC provides high-quality mechanical equipment and professional process technology to produce top-notch FDY. The principle of producing FDY filament is simple: under extremely high pressure, a pump squeezes the polymer melt through a fine spinneret, and then bundles the filaments into a line and winds it up. It sounds simple, but mastering high-precision and highly stable technology is very difficult, and CTMTC has achieved this.

In fact, CTMTC has been producing FDY for over 35 years, with over 2000 operating equipment and supplying to more than 10 countries. The processing speed of the FDY machine we provide is maintained at 4200-4500 meters per minute, and the maximum length of the bottom edge can reach 1680. The winding machine has both cam and double rotor types.

What will you get by choosing CTMTC’s FDY machine?

Firstly, you will receive a high-level FDY production solution. From the extruder to the specially designed spinning box, equipped with long-life spinning heads and components, from the melt to the cooling and comfortable quenching zone, all key components in the spinning system are made of well-known brands and specially designed in the system, suitable for producing top-grade FDY yarn. At the same time, the perfect winding structure inside the tube determines the excellent and smooth performance of subsequent processes such as adding bullets. Secondly, our equipment is capable of producing FDY filament with superior appearance. The system designed specifically for producing high-quality standards or special yarns is CTMTC‘s core competitiveness. It should be noted that all of our FDY production lines use ultra-high quality materials and accessories. Professional extruders, spinning pumps, spinning shafts, spinning components, cooling systems, and winding machines make it easy for you to have high-quality yarn. Thirdly, CTMTC’s FDY equipment has strong technical support and post maintenance capabilities, so you don’t have to worry about the post maintenance of the equipment. High quality machinery and experienced experts are the foundation for us to win the market. We have one-on-one technical personnel and service managers to provide technical support and ensure long-term spare parts services. We provide not only a textile machinery, but also a point-to-point solution.

Post time: Dec-05-2024