CTMTC FDY Machine

Solution To Produce FDY/Mother Yarn /Bi-co Filament Yarn Based On PET/PBT/PA6FCTMTC

Has The Mature Solution To Manufacture FDY

As Your Reliable Supplier, CTMTC Provide High Quality Machinery And Professional Process Technology To Produce Top-Level FDY

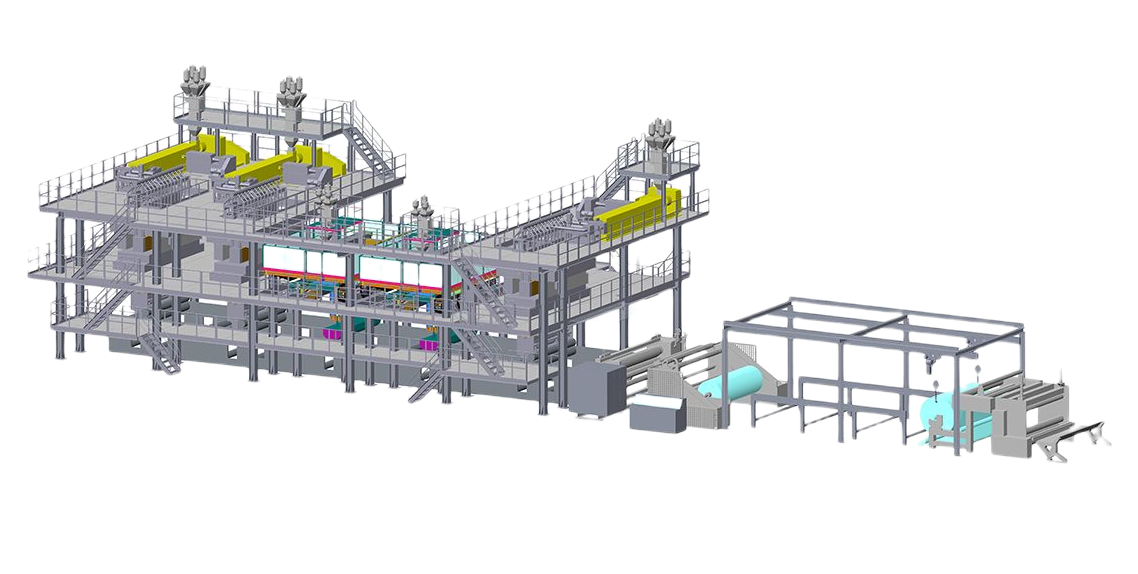

FDY Line

The principle of produce FDY yarn is very easy: with extremely high pressure, pumps press the polymer melt through micro-fine spinnerets , then the filament be bundled into threads and winded. It sounds very simple, while very hard to master high-precision and simultaneously extremely stability technology, which CTMTC does.

Manufacturing History

Over 35 years

Running

line

Over 2000 Pos

World

market

Supplied over 10 countries

The most important data at a glance

| FDY | |||||||

| Raw materials | PET,PBT,PA6,PP | ||||||

| D range | 30-500 | ||||||

| F range | 24-288 | ||||||

| Ends | 45089 | ||||||

| Process Speed(m/min) | 4200-4500 | ||||||

| Spinneret | φ50-φ120 | ||||||

| Quenching | Cross quenching/ EVO | ||||||

| BH Length(mm) | Max: 1680 | ||||||

| Winder | Cam type / Bi-rotor type | ||||||

| Final Application | Knitting Fabric, Weaving Fabric, Home Textile, Sewing yarn, Industrial yarn |

What You Will Get?

High Level FDY Production Solution

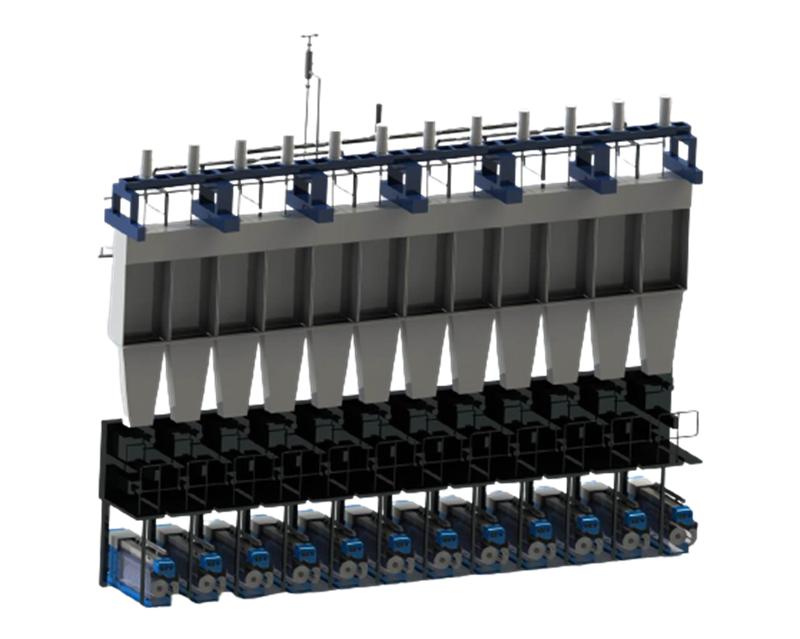

With good-performance spinning system, from extruder to special design spinning beam with long lifetime spinneret and spin packs , melt through to quenching area with comfortable cooling, all the key parts in spinning system with famous brand and special design in the system for top-level FDY yarn.

CTMTC- Winder as the heart of FDY production line with soft-touch make sure the positive influence on the FDY evenness, filament tension and CV% values.

The perfect package structure in bobbin determines downstream process such as texturing with excellent and smooth performance.

Out Standing & High Quality FDY Filament Appearance

Our core competence is system designed for the production of high-quality standard or specialty yarns. Whether polyester or polyamide 6, microfiber or high denier super-microfiber – CTMTC FDY technology will give impetus to your success on high-quality standard yarns.

The complete CTMTC FDY line using high quality materials and accessories. With professional extruder, spinning pump, spin beam, spin pack, quenching system and winder, you will get premium yarns. The bobbin package is flat and clear circle which benefit for downstream processing.

Sufficient Capacity On FDY Filament Yarn

As the leader manufacture in POY/FDY Spinning Machine in China, CTMTC cooperate with world famous companies on key parts to make sure top-level yarn quality and energy saving : Meiden, FAG, SMC, AB, Siemens, Dent, etc.

Cost-efficient Investment, Manufacturing & Maintenance

With adoption of CTMTC FDY line, your initial investment on machinery will save a lot, your cash flow will be much healthier, more finance can be invested into other fields, like capacity expanding, research development, business expanding etc. To guarantee your competition advantage, CTMTC adopts optimized production processes, efficient systems, sustainable technologies. Automation process and digital system make sure the machine running constantly and smoothly, less labor and cost needed;FDY system need long time maintenance, CTMTC can supply systems requiring minimum maintenance cost, there are one-on-one technician and service manager to offer support, and we can guarantee longtime spare parts service.

Strong Design & Technician Support

It is clearly sure what you need is not only one single machine, but solutions.

For years we continuously committed to provide real solution to enhance your success. High quality machinery and experienced experts is our foundation to win the market. And we can always be there during your whole business period. You will get reliable feasibility study report, professional design, high quality machinery and commissioning, stuff training, process support, if you are a newcomer of POY/FDY industrial. And you will get your own excellent manufacturing quality FDY spinning line and your own skilled technicians in the end; You will get latest technical support, market information in your expanding period for you make the decision; You will get our solution on the process no matter whatever you use polymer combinations of PET, PBT, PA6 or Bi-co, and Whatever you want to manufacture, Standard, high-denier or micro-yarns, polyester or polyamide, FDY, we will be at your side support, to help your long time success.

Video

Your CTMTC expert

Do you have any questions?

I am glad to be there for you

Michael Shi

CTMTC

medium

medium Inquiry

Inquiry