CTMTC Cold Pad Batch Dyeing Solution

Produce CPB dyeing solution in textile treatment systemCTMTC

Has Mature Technology And Experience On Cold Pad Batch Dyeing

As your reliable supplier, CTMTC will produce highest CPB dyeing range

Cold Pad Batch Dyeing

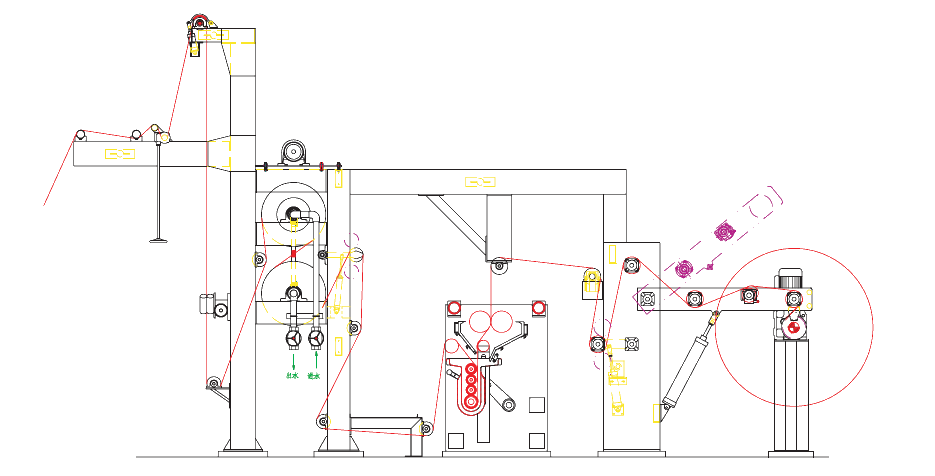

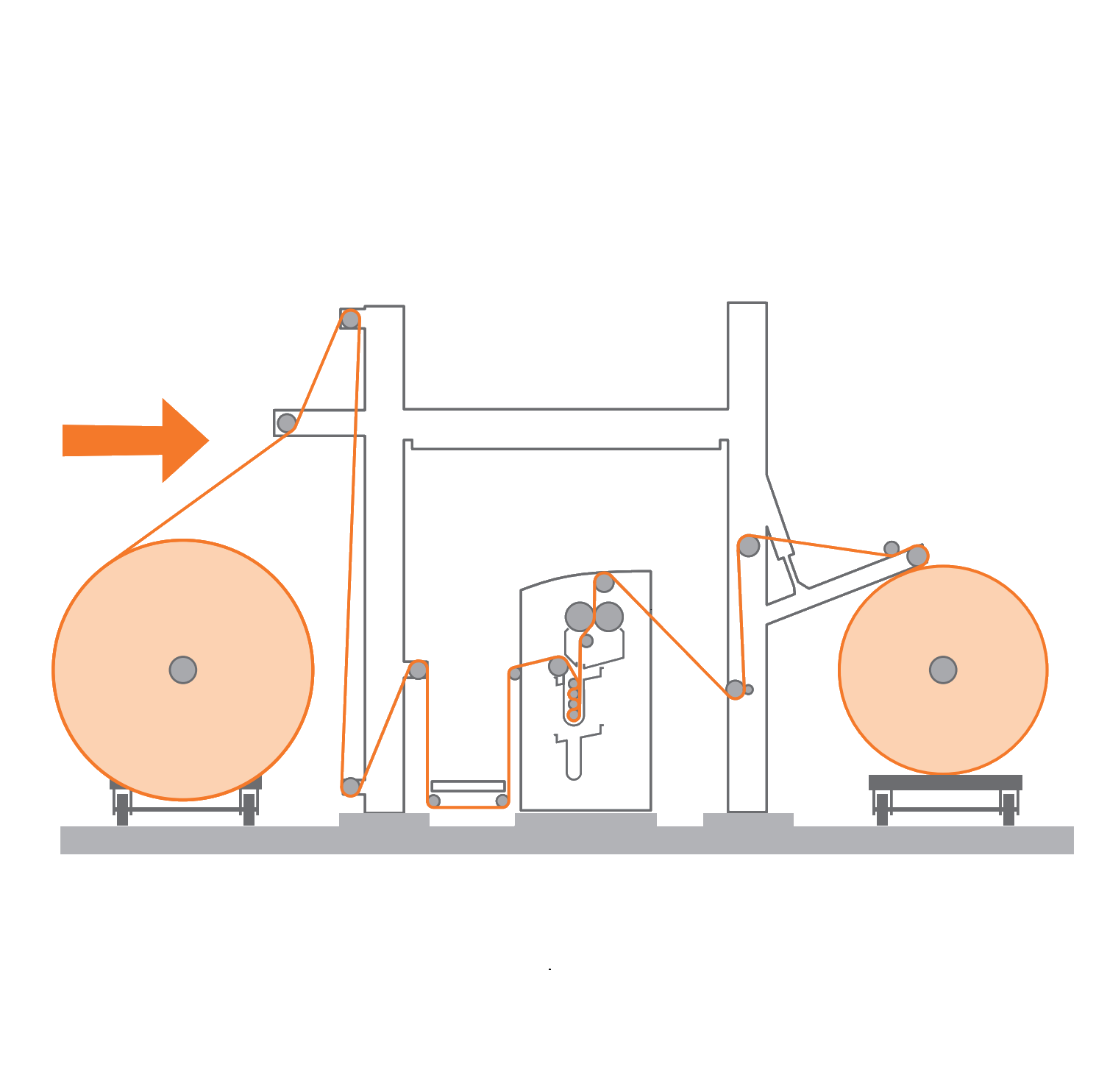

Cold pad batch dyeing machine is the easiest process of woven fabric dyeing. This machine is used for dyeing the fabric of cotton, hemp and their blends. Normally after mercerizing, fabric batcher is feed into the inlet of CPB machine , in which both dye & chemicals are added in the same bath to finish the dyeing process. And the fabric is passed over some free roller & guider. There is a compensator to control fabric open width entry & controlling fabric speed. Semi-durative processing can save the consumption on the cotton reactive dyeing.

Manufacturing History

Over 40 years

World

market

Supplied over 10 countries

The most important data at a glance

| Machine Name | Cold Pad Batch Dyeing Machine |

| Brand | CTMTC |

| Original | China |

| Roller Width | 1800-3600mm |

| Machine Speed Range | 15-70m/min |

| Fabric GSM | 100-450GSM |

| Drive | PLC, AC motor with inverter |

| Proportion pump | 1:4 |

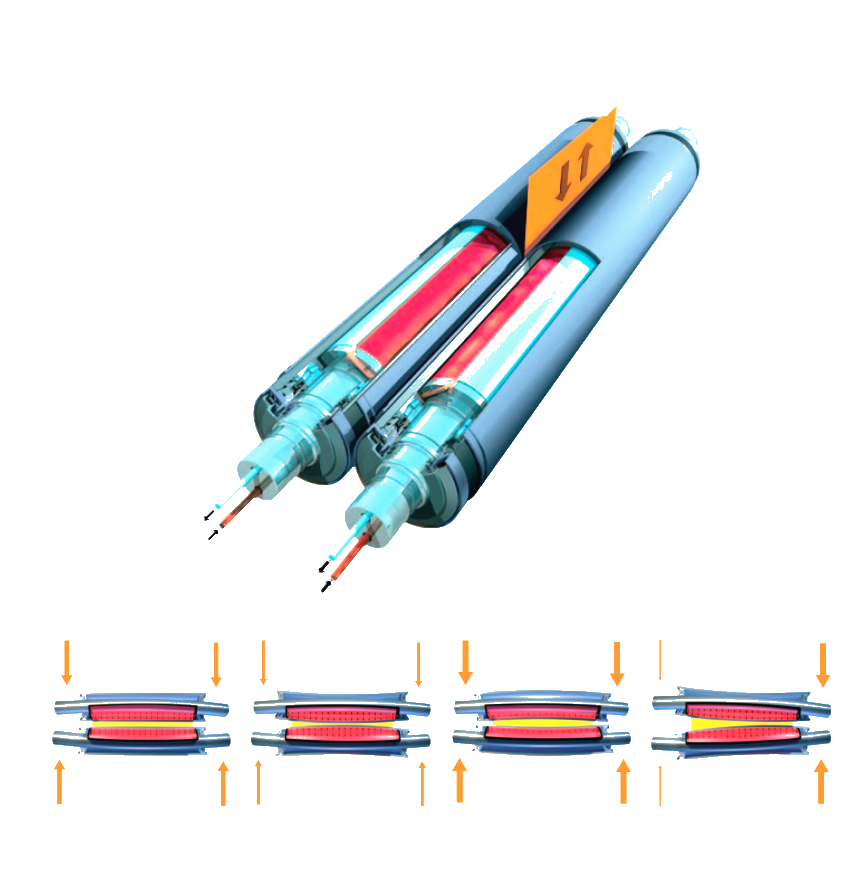

| Rubber material | NBR, Hardness: Shore70 |

| Fabric outlet | Winding from the center |

Your Benefits

First & Complete Cold Pad Batch Dyeing Solution

With years of experience and comprehensive textile competence, CTMTC built up a reliable process solution on both the machinery and dyeing process.

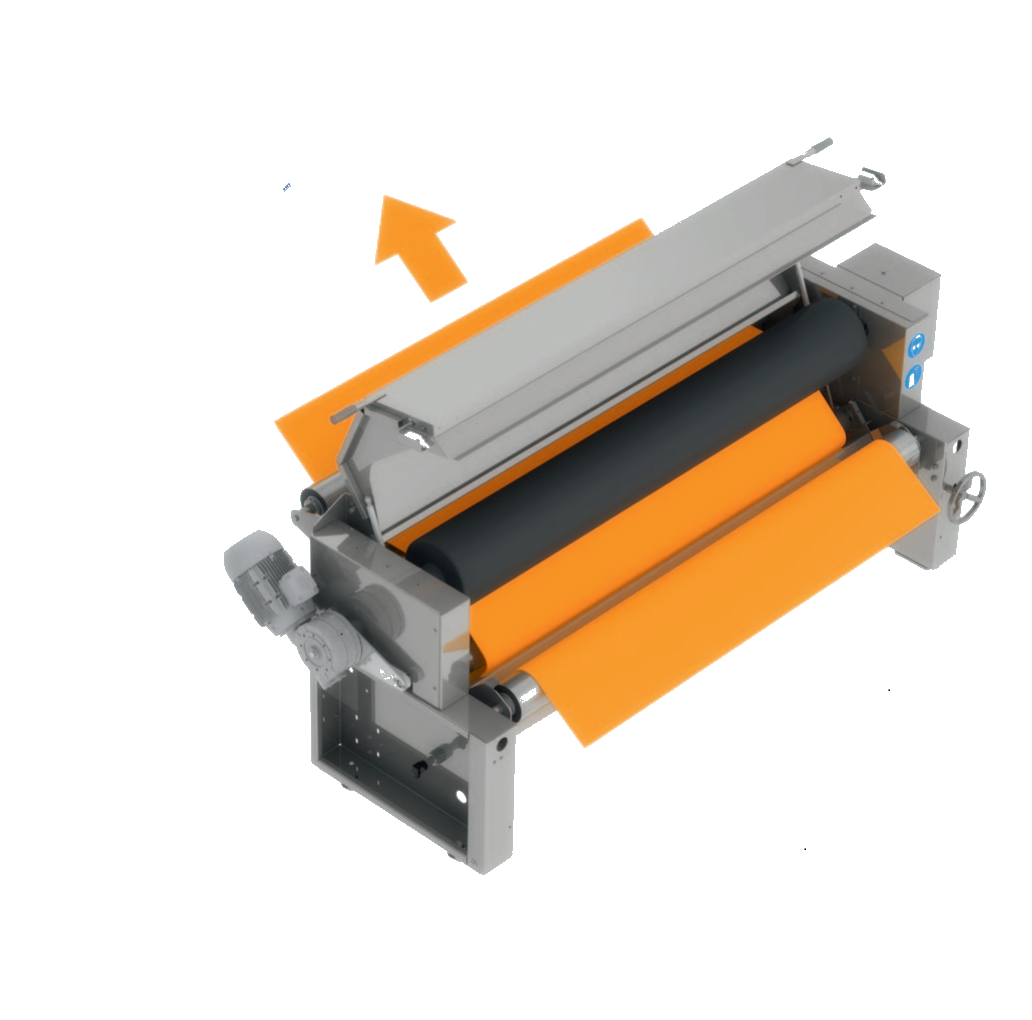

Adopt low level controlling to reduce the dye liquid in the trough at the real-time.

Equipped with freezing refrigeration to delay the reactive dye staff hydrolyzing.

The dyeing liquid has been cooled in the mixing tank.

The surface of fabric will be cooled after passing the cooling drums.

In order to remain the dyeing liquid remaining on the fabric, that means no directly contact between batching roller and fabric batch, we adopts fabric winding from the center.

Outstanding & High Fabric Quality & Appearance

Our core competence is mechanical system designed for the treatment of fabric. whether cotton, hemp or blends, CTMTC cold pad batch dyeing technology will continuously improve our performance and support the sustainability to help you produce high-quality standard finishing fabric.

After years of experience, CTMTC is backed by a large number of reference installations for each of the individual applications. All the components make sure to improve the fabric dyeing effect.

You will get out standing dyeing fabric on both capacity and appearance.

Cost-efficient On One Time Investment & Manufacturing & Maintenance

With adoption of CTMTC CPB Line, your initial investment on machinery will save a lot, your cash flow will be much healthier, more finance can be invested on other field, like business expanding, research development, labor training and so on.

To guarantee your competition advantage, CTMTC adopts optimized production processes, efficient systems, sustainable technologies. Automation process and digital system make sure the machine running constantly and smoothly, less labor needed and more energy saving; regular maintenance by expert technicians minimized unexpected downtimes, one-on –one technician and service manager to offer maintenance support and life long spare parts offering, not to mention CTMTC machine broken rate is far lower than the equivalent brand competitors, and your cost on maintenance will be very small.

Strong Design & Technician Support

It is clearly sure what you need is not only one single dyeing machine, but solutions. For years we continuously committed to provide real solution to enhance your success. High quality machinery and experienced experts is our foundation to win the market. And we can always be there during your whole business period.

You will get reliable feasibility study report, high quality machinery, professional design at your first step. And you will get commissioning, stuff training, process know-how during your production. We will be here during all your life cycles.

And our range of goods and service is continuously optimized and supplemented. We will improve the entire value-added chain to you with quality produces and services. And all these action will help you begin your business quickly and smoothly.

Video

Your CTMTC expert

Do you have any questions?

I am glad to be there for you

Mao Yuping

CTMTC

medium

medium Inquiry

Inquiry